Conductive FIBCs

01.Conductive flexible container bags

About conductive flexible container bags

Conductive flexible container bags are made to prevent disasters such as dust explosion caused by electrostatic discharge when filling and discharging. There are three types of them (type B to type D) classified by discharge prevention mechanism. On the other hand, normal flexible container bags, which are made without any special electrostatic measures, are called type A.

Standard of conductive flexible container bags

Conductive flexible container bags(Type C)

Conductive flexible container bags(Type C)- 2005

The first international standard for flexible container bags against static electricity (IEC 61340-4-4:2005) was enacted. In Japan, it was established and published as JISC 61340-4-4:2009 based on the international standard.

- 2012

The second edition (IEC 61340-4-4:2012) was approved and published. From the viewpoint of electrostatic measures, flexible container bags have been classified into four types, and their structural and performance requirements have been defined. Inner bags have been also classified into three types. Requirements for each bag have been defined, and the combinations of flexible container bags and inner bags that can be applied according to the usage conditions have been specified.

- 2015

In Japan, JIS C 61340-4-4:2015 was newly established and published with reference to IEC 61340-4-4:2012.

※IEC = International ElectrotechnicalCommission

02.Conductive flexible container bags - Features of each type

Type A

Non-conductive type:

General flexible container bags without any special measures against static electricity.

Type B

Anti-static type:

Flexible container bags designed to suppress the occurrence of creeping discharge by dielectric breakdown(※), which reduces static electricity. They can be used in an environment where measures against electrostatic disasters are taken and a dusty environment ignition energy exceeds 3mJ.

※Dielectric breakdown: The phenomenon of losing insulation above a certain limit, as the voltage applied to an insulator increases.

Type C

Conductive type:

The flexible container bags are made of mixed fabric in which carbon steel or conductive yarn with a silver core are woven at regular intervals. Our system is designed to quickly reduce static electricity generated when filling and discharging granular materials, and not to store energy that could lead to disasters.

Type D

Harmless discharge type:

This type of flexible container bag produces corona discharges before producing brush discharges (which have a risk of ignition) or creeping discharges when the bags get electrified and then the conductor approaches. Corona discharge does not set a fire because it’s a very weak discharge with almost no sound or light, also referred to as silent discharge. In this type, the original fabric of the flexible container bag itself generates corona discharge, and doesn’t need to ground.

Combination of conductive flexible container bags and inner bags

The following three types of inner bags are suitable for conductive flexible container bags.

L1 Inner bag

A highly conductive inner bag with a surface resistivity (under the condition of 23±2℃ and 20±5% of relative humidity) of 1.0×107Ω or less on at least one side. During work, the potential is reduced to 300V or less by grounding this, and no spark discharge occurs. Poor grounding can easily cause spark discharge, so care must be taken when handling.

Flexible container bags that can be combined: Type C only

L2 Inner bag

An inner bag with a surface resistivity (under the conditions of 23±2℃ and 20±5% of relative humidity, 23±2℃ and 60±10% of relative humidity ) of 1.0×109Ω or more and 1.0×1012Ω or less on at least one side. This type should be used with grounding in principle, but it has the advantage that ignitable discharge is unlikely to occur even if the grounding is poor. Thus, it is the most versatile inner bag.

Flexible container bags that can be combined: Type B, Type C, Type D

L3 Inner bag

Insulating inner bag with surface resistivity (under the conditions of 23±2℃ and 20±5% relative humidity) of more than 1.0×1012Ω on both sides, but dielectric breakdown voltage is less than 4kV. While this inner bag does not cause creeping discharge, it cannot prevent brush discharge.

Flexible container bags that can be combined: Type B only

03.Combination of conductive FIBCs and inner bags

Features of inner bags

The combination list of conductive flexible container bags and inner bags

| Inner bags type | Inner surface resistivity | Outer surface resistivity | Dielectric breakdown voltage | Thickness | Possible combination of flexible container bags |

|---|---|---|---|---|---|

| L1 | 1.0×107or less | 1.0×107or less | No measurement required | No limit | C |

| 1.0×107or less | 1.0×1012or less | No measurement required | No limit | ||

| 1.0×1012or less | 1.0×107or less | No measurement required | No limit | ||

| 1.0×107or less | More than 1.0×1012 | Less than 4kV | No limit | ||

| More than 1.0×1012 | 1.0×712or less | Less than 4kV | Less than 700μm | ||

| L2 | 1.0×107 - 1.0×1012 | 1.0×109 - 1.0×1012 | No measurement required | No limit | B,C,D |

| 1.0×107 - 1.0×1012 | More than 1.0×1012 | Less than 4kV | No limit | ||

| More than 1.0×1012 | 1.0×109 - 1.0×1012 | Less than 4kV | Less than 700μm | ||

| L3 | More than 1.0×1012 | More than 1.0×1012 | Less than 4kV | No limit | B |

Case 1

Inner bags type:L1

Inner surface resistivity:1.0×107 or less

Outer surface resistivity:1.0×107 or less

Dielectric breakdown voltage:No measurement required

Thickness:No limit

Possible combination of flexible container bags:C

Case 2

Inner bags type:L1

Inner surface resistivity:1.0×107 or less

Outer surface resistivity:1.0×1012 or less

Dielectric breakdown voltage:No measurement required

Thickness:No limit

Possible combination of flexible container bags:C

Case 3

Inner bags type:L1

Inner surface resistivity:1.0×1012 or less

Outer surface resistivity:1.0×107 or less

Dielectric breakdown voltage:No measurement required

Thickness:No limit

Possible combination of flexible container bags:C

Case 4

Inner bags type:L1

Inner surface resistivity:1.0×107 or less

Outer surface resistivity:More than 1.0×1012

Dielectric breakdown voltage:Less than 4kV

Thickness:No limit

Possible combination of flexible container bags:C

Case 5

Inner bags type:L1

Inner surface resistivity:More than 1.0×1012

Outer surface resistivity:1.0×1012 or less

Dielectric breakdown voltage:Less than 4kV

Thickness:Less than 700μm

Possible combination of flexible container bags:C

Case 6

Inner bags type:L2

Inner surface resistivity:1.0×107 - 1.0×1012

Outer surface resistivity:1.0×109 - 1.0×1012

Dielectric breakdown voltage:No measurement required

Thickness:No limit

Possible combination of flexible container bags:B,C,D

Case 7

Inner bags type:L2

Inner surface resistivity:1.0×107 - 1.0×1012

Outer surface resistivity:More than 1.0×1012

Dielectric breakdown voltage:Less than 4kV

Thickness:No limit

Possible combination of flexible container bags:B,C,D

Case 8

Inner bags type:L2

Inner surface resistivity:More than 1.0×1012

Outer surface resistivity:1.0×109 - 1.0×1012

Dielectric breakdown voltage:Less than 4kV

Thickness:Less than 700μm

Possible combination of flexible container bags:B,C,D

Case 9

Inner bags type:L3

Inner surface resistivity:More than 1.0×1012

Outer surface resistivity:More than 1.0×1012

Dielectric breakdown voltage:Less than 4kV

Thickness:No limit

Possible combination of flexible container bags:B

- *L1、L3→23±2℃ and relative humidity 20±5%.

- *L2→23±2℃ and relative humidity 20±5%, 23±2℃ and relative humidity 60±10%.

- *When the L2 inner bag is used in type C, the generated current must not exceed 3μA.

- Click here for estimates on electrostatic measures flexible container bags.

04.Usage environment of conductive flexible container bag

About hazardous areas

conductive flexible container bags are mainly used in places called hazardous areas where dust and oxygen air can mix and create an explosive atmosphere. We will introduce details of danger zones where conductive flexible container bags are used.

Hazardous area classification

| Classification | Danger zone details | |

|---|---|---|

| Ⅰ | Mine pit where underground explosive gas is generated. | |

| Ⅱ | A place other than a mine pit, where an explosive gas atmosphere consisting of: | |

| A | General ignitable gas / vapor (hexane, methane, acetone, etc.) | |

| B | Highly ignitable gas / vapor (diethyl ether, ethylene, cyclopentane, etc.) | |

| C | Gas / vapor with extremely high ignitability (hydrogen, acetylene, carbon disulfide, etc.) | |

| Ⅲ | A place other than inside the mine, where a dust explosion atmosphere consisting of: | |

| A | Flammable floating matter | |

| B | Non-conductive dust (Electrical resistivity exceeds 1kΩ・m) | |

| C | Conductive dust (Electrical resistivity 1kΩ・m or less) | |

Hazardous area classification:Ⅰ

Danger zone details:Mine pit where underground explosive gas is generated.

Hazardous area classification:Ⅱ

Danger zone details:A place other than a mine pit, where an explosive gas atmosphere consisting of:

A:General ignitable gas / vapor (hexane, methane, acetone, etc.)

B:Highly ignitable gas / vapor (diethyl ether, ethylene, cyclopentane, etc.)

C:Gas / vapor with extremely high ignitability (hydrogen, acetylene, carbon disulfide, etc.)

Hazardous area classification:Ⅲ

Danger zone details:A place other than inside the mine, where a dust explosion atmosphere consisting of:

A:Flammable floating matter

B:Non-conductive dust (Electrical resistivity exceeds 1kΩ・m)

C:Conductive dust (Electrical resistivity 1kΩ・m or less)

- *Note1 Substances belonging to a certain explosion group form around a danger zone of the explosion group.

- *Note2 Ignition danger increases in the order of A,B, and C.

About danger zones

Zone classification

| Classification | Zone details |

|---|---|

| Zone 0 | A place where an explosive atmosphere consisting of a mixture of air and flammable substances in the form of gas, vapor or mist exists continuously, for a long time, or frequently. |

| 1 | A place where an explosive atmosphere consisting of a mixture of air and flammable substances in the form of gas, vapor or mist may occasionally occur during normal operation. |

| 2 | A place where an explosive atmosphere consisting of a mixture of air and flammable substances in the form of gas, vapor or mist may occur during normal operation, but is generated for a short time. |

| 20 | A place where an explosive atmosphere in which flammable dust forms dust clouds in the air exists continuously, for a long time, or for a short time but frequently. *Note) A place where a large amount of dust exists but dust clouds don’t exist continuously, for a long time, or frequently is not included in this zone. |

| 21 | A place where an explosive atmosphere, which forms flammable dust as dust clouds in the air, may occasionally occur during normal operation. |

| 22 | A place where an explosive atmosphere, which forms flammable dust as dust clouds in the air, may occur during normal operation, but is generated for a short time. |

Zone 0

Details : A place where an explosive atmosphere consisting of a mixture of air and flammable substances in the form of gas, vapor or mist exists continuously, for a long time, or frequently.

Zone 1

Details : A place where an explosive atmosphere consisting of a mixture of air and flammable substances in the form of gas, vapor or mist may occasionally occur during normal operation.

Zone 2

Details : A place where an explosive atmosphere consisting of a mixture of air and flammable substances in the form of gas, vapor or mist may occur during normal operation, but is generated for a short time.

Zone 20

Details : A place where an explosive atmosphere in which flammable dust forms dust clouds in the air exists continuously, for a long time, or for a short time but frequently.

*Note : A place where a large amount of dust exists but dust clouds don’t exist continuously, for a long time, or frequently is not included in this zone.

Zone 21

Details : A place where an explosive atmosphere, which forms flammable dust as dust clouds in the air, may occasionally occur during normal operation.

Zone 22

Details : A place where an explosive atmosphere, which forms flammable dust as dust clouds in the air, may occur during normal operation, but is generated for a short time.

Applications of conductive flexible container bag

Because the ignition ability due to electrostatic discharge differs depending on the type of discharge, etc., the performance and specifications required for conductive flexible container bags depend on the application of flexible container bags. We introduce the application conditions for types A,B,C, and D of conductive flexible container bags.

Applications of conductive flexible container bag

| Content minimum ignition energy (MIE) | Usage environment | Available flexible container bags |

|---|---|---|

| More than 1000mJ | Non-flammable atmosphere | A、B、C、D |

| Dust hazardous area | B、C、D | |

| Gas or dust hazardous area | C、D | |

| 3mJ - 1000mJ | Non-flammable atmosphere | B、C、D |

| Dust hazardous area | B、C、D | |

| Gas or dust hazardous area | C、D | |

| Less than 3mJ | Non-flammable atmosphere | C、D |

| Dust hazardous area | C、D | |

| Gas or dust hazardous area | C、D |

Content minimum ignition energy (MIE) : More than 1000mJ

Non-flammable atmosphere : A、B、C、D

Dust hazardous area : B、C、D

Gas or dust hazardous area : C、D

Content minimum ignition energy (MIE):3mJ - 1000mJ

Non-flammable atmosphere : B、C、D

Dust hazardous area : B、C、D

Gas or dust hazardous area : C、D

Content minimum ignition energy (MIE):Less than 3mJ

Non-flammable atmosphere : C、D

Dust hazardous area : C、D

Gas or dust hazardous area : C、D

05.Our track record of conductive flexible container bags

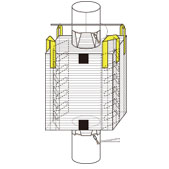

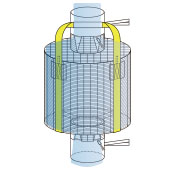

An example of Type C flexible container bags

In recent years, we have received inquiries from a very large number of customers, especially about Type C flexible container bags (conductive flexible container bags) among conductive flexible container bags. We will introduce an example of Type C flexible container bags that we have manufactured so far.

Sample 1

Standard type

Sample 2

Square 4-point hanging type

Sample 3

Input port fully open type

Sample 4

Square partition wall attached type

Sample 5

L2 inner bag sewing type